PrimeVOLT launches new PV inverters for high power solar modules HOT!

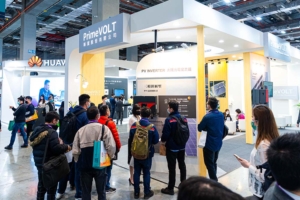

Driven by the global Net Zero Emission commitment and the pressing energy demands as the world bounces back from the pandemic, the number of solar photovoltaic installations is on an impressive upsurge. And this comes with the booming growth of solar PV converters/inverters. Responding to the trend of high-power modules, such as M10 and G12 launched recently by major module manufacturers, PrimeVOLT, a leading solar inverter supplier from Taiwan, has unveiled its latest generation of high-current solar inverters, including 30kW, 60kW and 75kW models. These products are tailored to perfection for compatibility with high power solar panels, promising users a more stable and efficient solar power generation experience.

PrimeVOLT’s latest series of high-current solar inverters not only offer outstanding compatibility with high-power panels but are also highly cost-competitive, positioning the company as an important driving force towards a greener future.

As the world becomes increasingly aware of the pressing need for green energy, solar power generation has been emerged as a frontrunner among sustainable solutions. With a Taiwan government-mandated plan to reach 20GW solar capacity by 2025, domestic solar modules have been pushing towards higher power modules exceeding 500W, aiming to reduce construction costs and achieve Net Zero Emission by 2050. As a crucial component of solar power generation system, the quality and operational stability of PV inverters play a pivotal role in enhancing power generation efficiency and overall safety. With the rising demand for high-power modules, the market for converters that are compatible with these modules is set to grow rapidly, offering the innovative products to meet the needs of the industry.

The new models not only inherit the defining features of PrimeVOLT’s mass-produced products, but also boast unparalleled capacity upgrades. With a focus on flexibility and efficiency, these cutting-edge devices are designed to withstand higher currents in the string input section, enabling a highly efficient output of solar modules that can support large-scale solar power generation systems. The new models can cater to a wide range of application scenarios and adapt to various power environments. For instance, the 75kW high power inverter model features 4 groups of MPPT, 8 groups of DC input, and a string input current of up to 19.5A, making it ideal for next-generation modules such as M10 and G12. It can also support three-phase & three-wire / three-phase & four-wire power systems, complete with a built-in DC junction box and virtual power compensation function. Optional AFCI (DC arc detection) functionality further enhances the safety performance. In addition, these models have passed national information security level 2 certification to ensure data protection. With comprehensive after-sales service support, customers can rest assured that they will receive worry-free service throughout the process. By reducing the cost and losses of transformers as customers switch between 440/460V systems and increasing power generation revenue, the new series from PrimeVOLT prove to be a game-changer in the solar energy industry.

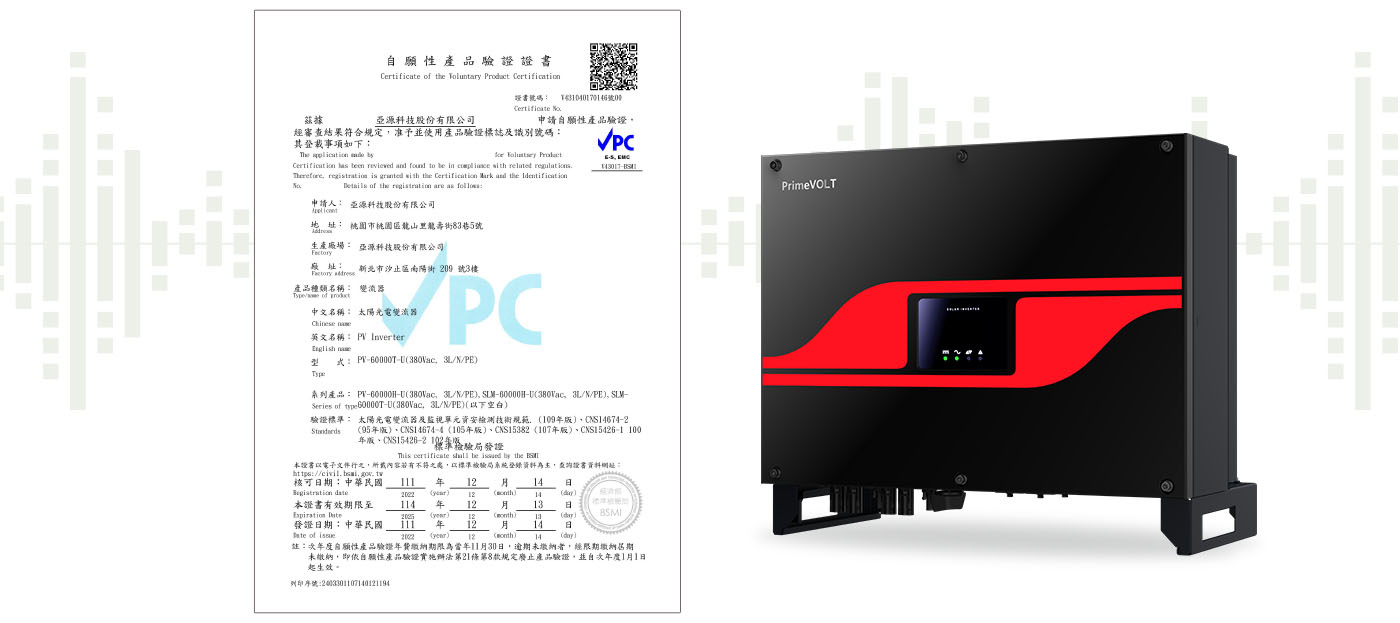

PrimeVOLT’s full range of solar inverters are all compliant with the “VPC Voluntary Product Verification” policy requirements.

PrimeVOLT, a leading brand in green energy, is affiliated with Taiwan’s renowned power supply giant APD. The company is dedicated to delivering top-quality converter/inverter products and professional technical support services to customers worldwide. Their commitment to excellence has earned them the highest honor in the solar industry in Taiwan, the “Golden Energy Award for Quality Solar Products,” for two consecutive years in 2021 and 2022. The company’s latest launch, the high-current solar converters, marks a significant milestone in the development of large-scale and high-efficiency solar systems. PrimeVOLT’s unwavering focus on research and innovation in technology aims to enhance the performance and reliability of their solar products, pushing the boundaries of the green energy industry. With top-notch products and services, PrimeVOLT will keep offering cutting-edge solutions that cater to the diverse needs of customers, contributing to a greener planet.

【About PrimeVOLT】

PrimeVOLT is a leading brand in green energy, affiliated with Taiwan’s renowned power supply giant APD. The company is dedicated to designing and manufacturing solar inverters for customers worldwide. Its robust R&D capabilities, coupled with high-quality products and professional services, have made PrimeVOLT the number one brand in the PV inverter industry in Taiwan. Moving forward, PrimeVOLT will continue to provide innovative products and energy storage solutions to contribute to a green and sustainable future.

Learn more:https://primeVOLT.com.tw